80deg16minW

Vital Reserves Team

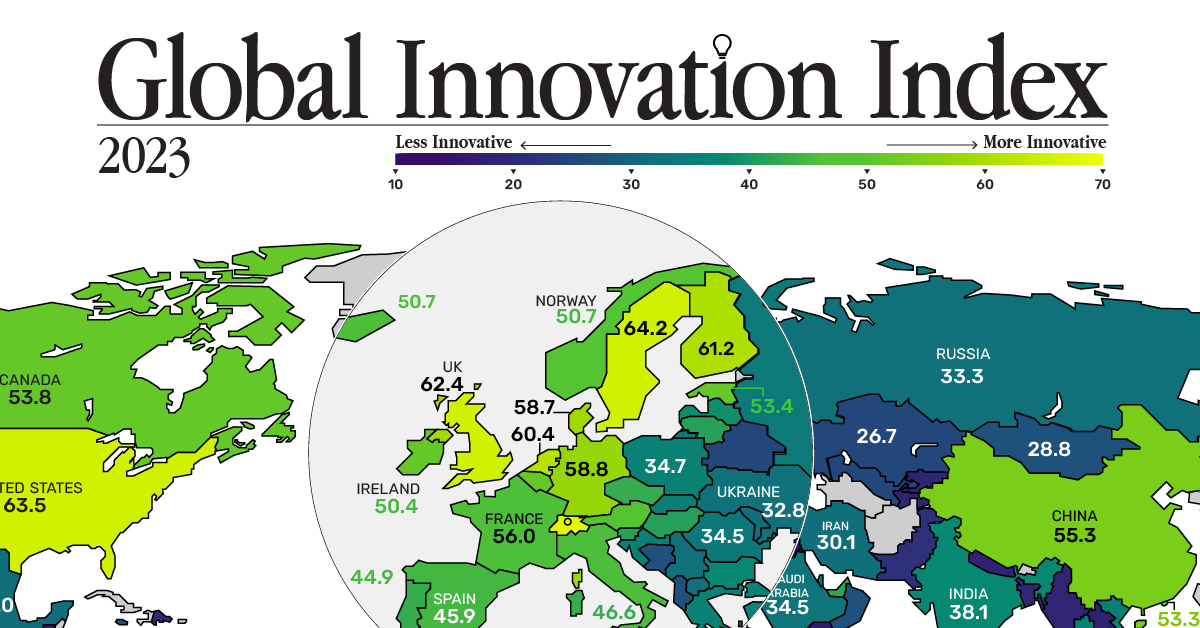

Our failures to innovate & adapt to global changes have proven to be extremely costly. We're all too often far too late to the party.

Oh.

Our failures to innovate & adapt to global changes have proven to be extremely costly. We're all too often far too late to the party.

That's an exaggeration Steve - out tech and pharma industry is one of the best the best in the World, if not by far the best in Europe...Our failures to innovate & adapt to global changes have proven to be extremely costly. We're all too often far too late to the party.

www.visualcapitalist.com

www.visualcapitalist.com

National Service .... not just in the armed forces but including projects that make a difference in peoples lives.

If we're at the forefront then why does it always feel like we're lagging well behind?That's an exaggeration Steve - out tech and pharma industry is one of the best the best in the World, if not by far the best in Europe...

Although, overall for all industries we're ranked 3rd in Europe and 4th overall in the World - which means we're punching above our World economy size and ranking...

I don't feel that and never have and to be honest amongst all the businesses my businesses work with, it's not an opinion I've ever heard expressed.If we're at the forefront then why does it always feel like we're lagging well behind?

I'm involved in the automotive sector which let's be frank, has faced many difficulties when it comes to manufacturing within the UK. Investment is there but it always feels like we're late to the party somehow. That being said £25M has been invested in new technologies which should see us through the worst of it. I'm still not seeing the backing we should receive though despite the adaptability across our plants & the range of products we produce. This includes everything from combustion products, hybrid & full electric. Unless we are willing to go full electric the grants simply aren't there which is a tad unreasonable considering the lack of time in which we've been given to prepare for these changes.I don't feel that and never have and to be honest amongst all the businesses my businesses work with, it's not an opinion I've ever heard expressed.

Some will gripe about having to compete with government subsidised industries, but they're normally the shrinking one/last century ones who haven't moved on, or now can't.

The Stats and facts don't lie, apart from the South of Ireland (which is frowned upon by the EU and will in the next few years bought to heel) we have one of the best business tax regimes in Europe - which is why the UK STILL attracts the second-highest inwards foreign investment in Europe.

Given our size i can only see us as our glass being 80% full but with 20% hard problems because of our generally liberal lasse faire laws and outlook.

Looking at the facts, there really isn't any other logical interpretation that makes sense.

Of course, we have our challenges, and that's what will dominate the next election, but don't take short term anger as a reflection of where overall we stand in the World.

Out of interest, what backing do you think is lacking?I'm involved in the automotive sector which let's be frank, has faced many difficulties when it comes to manufacturing within the UK. Investment is there but it always feels like we're late to the party somehow. That being said £25M has been invested in new technologies which should see us through the worst of it. I'm still not seeing the backing we should receive though despite the adaptability across our plants & the range of products we produce. This includes everything from combustion products, hybrid & full electric. Unless we are willing to go full electric the grants simply aren't there which is a tad unreasonable considering the lack of time in which we've been given to prepare for these changes.

The issues are complex so i don't really want to go into them right now. What i will say is this is a joint venture (which is common in this particular sector nowadays) which will produce multiple products which will go into a number of different vehicles. So there are a number of difficulties we are trying to overcome at the moment & the current government are not helping matters one jot.Out of interest, what backing do you think is lacking?

I'll declare an interest, the quicker we go all electric in my opinion, the better - i'd make more money if we did

It just gets better.

Just received an update regarding the car. The work won't be completed until the 9th now due to the increased backlog. When pressed they couldn't give a definitive answer as to why it will take so long or even if it would be ready to collect on that date. The world's gone barking mad.

Realistically, What could they do?The issues are complex so i don't really want to go into them right now. What i will say is this is a joint venture (which is common in this particular sector nowadays) which will produce multiple products which will go into a number of different vehicles. So there are a number of difficulties we are trying to overcome at the moment & the current government are not helping matters one jot.

That's just great news.

The Future of the Automotive Industry | WDA Automotive Marketing

What does the future hold for the automotive industry? In this blog, we look into the new and exciting technologies to keep an eye on...wda-automotive.com

"The automotive industry is currently facing a major supply chain shortage, that is set to continue throughout 2024. This shortage is being caused by a combination of different factors, including increased demand for vehicles, disruptions in global trade, and supply chain bottlenecks.

One of the main causes of the supply chain shortage is the high and unexpected demand for new vehicles. With the economy still recovering from the COVID-19 pandemic and lockdowns, more and more people are looking to buy new cars. This increase in demand is putting a strain on the supply chain, as manufacturers struggle to keep up with the number of orders.

Another major factor contributing to the supply chain shortage is disruptions in global trade. The pandemic has caused major disruptions in trade routes and shipping lanes, making it difficult for manufacturers to get the parts and materials they need to build the cars. Additionally, Russia’s invasion of Ukraine has caused some difficulties with trade barriers, making it difficult for manufacturers to import the parts and materials that they need.

Supply chain bottlenecks are also contributing to the automotive supply chain shortage. These bottlenecks include everything from shortages of raw materials to problems with logistics and transportation.

Overall, the automotive supply chain shortage is a major issue that is affecting the entire industry. Manufacturers are struggling to keep up with demand, and many are having to delay production or cut back on their output. This is leading to higher prices for consumers and a shortage of vehicles on the market..."

Add to the above the now essential need to keep away from the Arabian Gulf and transit through the Egyptian canal and you'll see that the real world embodiment of that is not have the spares on shelves to fix cars/lorries and boats in a normal 'timely' manner...

What you're experiencing, Steve is the sharp end of all these disruptions...it has got better but progress has been slowed by all of the above!

They could & should be doing a lot more.Realistically, What could they do?

I wince a bit at broad brush comments like that, only as more often than not when I've investigated company issues in manufacturing; in my personal experience, it all leads back to management failings to act in a timely manner or rebuild planning ..etc etc...that said, the one key area for me that they've been slow to act upon is cheap Chinese product dumping - but those days too are about to end abruptly..

Intresting SP but forgive me but most brands have gone almost 100% mild hybrid and that is a worry ... why? because the Service do not know how to deal with them and the warning light reports.I'm involved in the automotive sector which let's be frank, has faced many difficulties when it comes to manufacturing within the UK. Investment is there but it always feels like we're late to the party somehow. That being said £25M has been invested in new technologies which should see us through the worst of it. I'm still not seeing the backing we should receive though despite the adaptability across our plants & the range of products we produce. This includes everything from combustion products, hybrid & full electric. Unless we are willing to go full electric the grants simply aren't there which is a tad unreasonable considering the lack of time in which we've been given to prepare for these changes.

US me ole mukka that's a ditto ere!Hard to get involved in the issues you all are having across the pond...hell here in the states we are about to have our 'WTF are we doing' election.

You wouldn't wish that on anybody.Hard to get involved in the issues you all are having across the pond...hell here in the states we are about to have our 'WTF are we doing' election.

Thats true Steve, but like I said to US its a ditto ere.You wouldn't wish that on anybody.